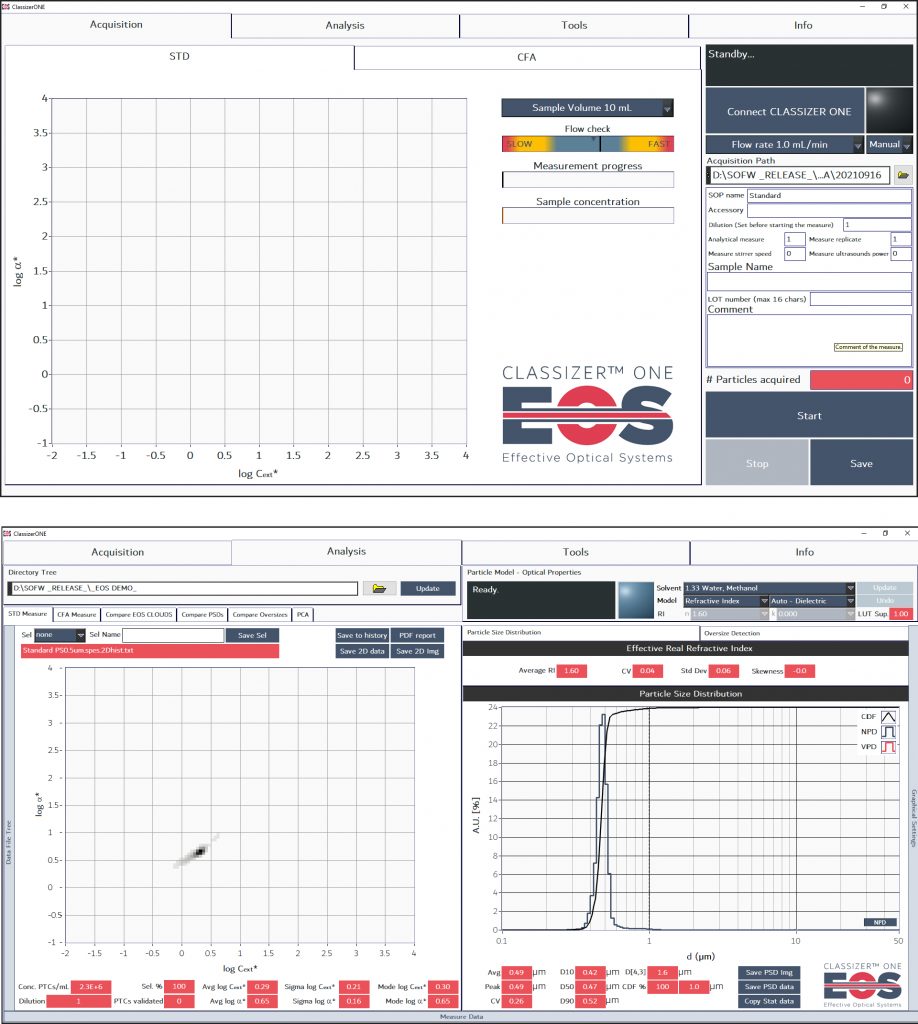

USER FRIENDLY CONTROL & EVALUATION SOFTWARE PLATFORM

All-in-one Classizer™ software platform with dedicated tabs for acquisition and analysis offers intuitive solutions for easy-to-use and reliable measurements. Standard operations and add-ons for advanced data acquisition and analysis are available and ready to use. Tailored Operative Procedures can be developed in the software to fit user needs.

Several internal checks are performed continuously to ensure to the user high quality and reliability of the SPES / SPES² / SPESell data. Warnings and expert advices are provided to user in real time during the data acquisition to save time and increase the quality of the results.

- User-friendly Interface

- No calibrations needed

- Robust Internal checks

- Real-time / In-Line / On-Line

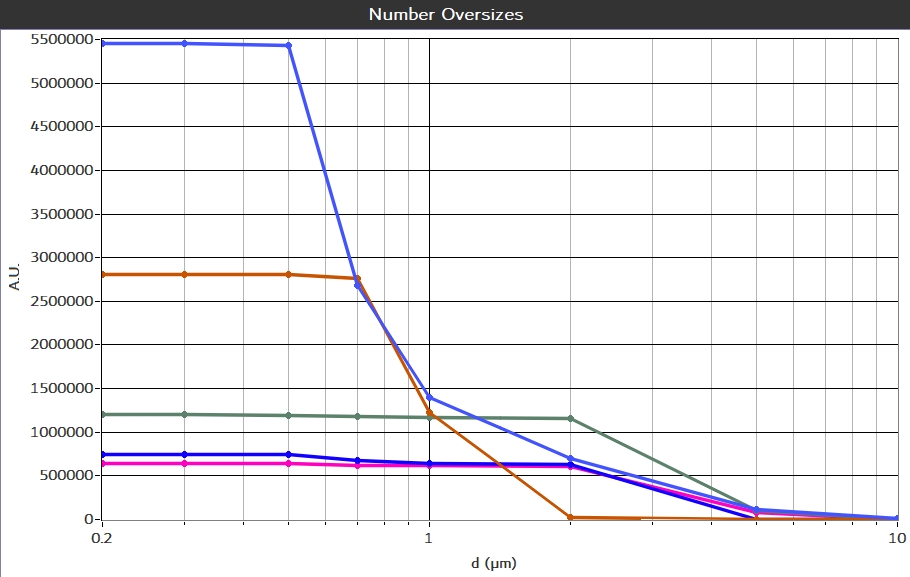

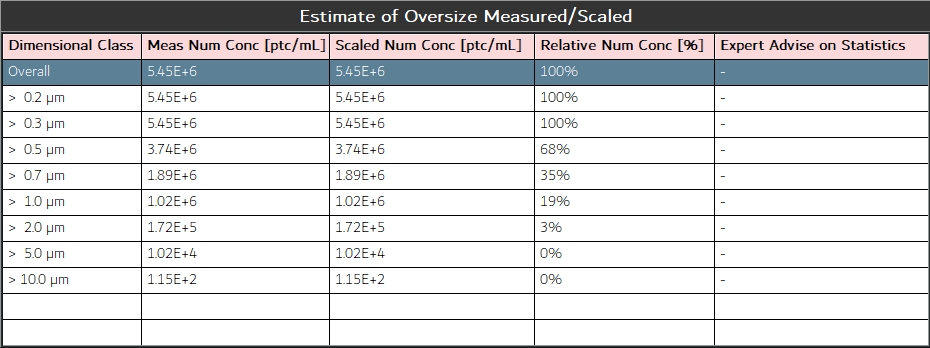

- Effective Oversize Analysis

- Uplad and Use Your Theory

- Customisable On Demand!

Comments and operator observations can be added to data during acquisition and analysis. Data are saved continuously in standard and Continuous Flow Analysis CFA mode limiting data loss and unintentional file overwriting. Custom solutions, analysis, and communication protocols are possibile via dedicate software packages and Add-Ons.

Analysis tab allows the operator to have the sample characteristics at a glance. EOS Classizer™ software provides many ways to perform a thorough analysis and retrieve valuable information precluded to standard and ordinary particle sizers and counters. Advance knowledge of products based on particles is finally achievable.

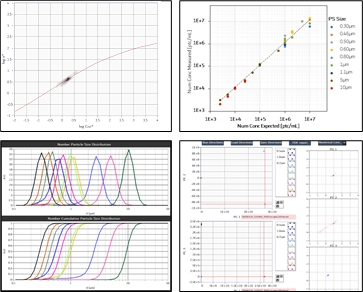

Thanks to the unique EOS CLOUDS and SPES data, the user can easily select any single particle population detected in the fluid and represented in the 2D histogram. Numerical particle size distribution, statistical parameters and concentration are retrieved accordingly to the selection and/or to the whole sample. Advanced feature as aggregation state, particle payload and aspect ratio are provided via software add-on. Advanced algorithms as Principal Component Analysis (PCA) are available to compare and correlate the behaviour of the single components in heterogeneous products and for batch-to-batch and raw material Quality Controls.

Default analysis assumes particles as standard dielectric spherical particles. Benefits from SPES technology loading specific data library for the unprecedented, classification, analysis, and interpretation of

- core-shell and payload estimate

- particle aging and shelf life

- aggregates and meso-porosity

- non-spherical microparticles

- absorbing and metallic materials

- and any of your specific needs!

Oversize Analysis. Compare batches oversizes defining custom oversize values and report data using tables and graphs.