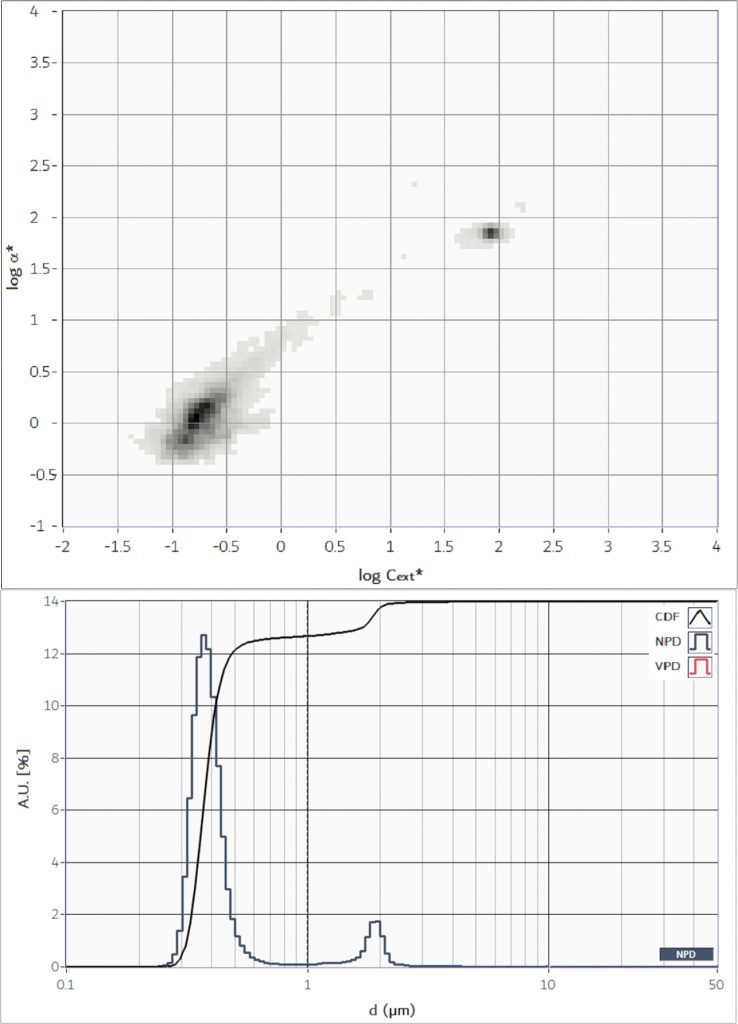

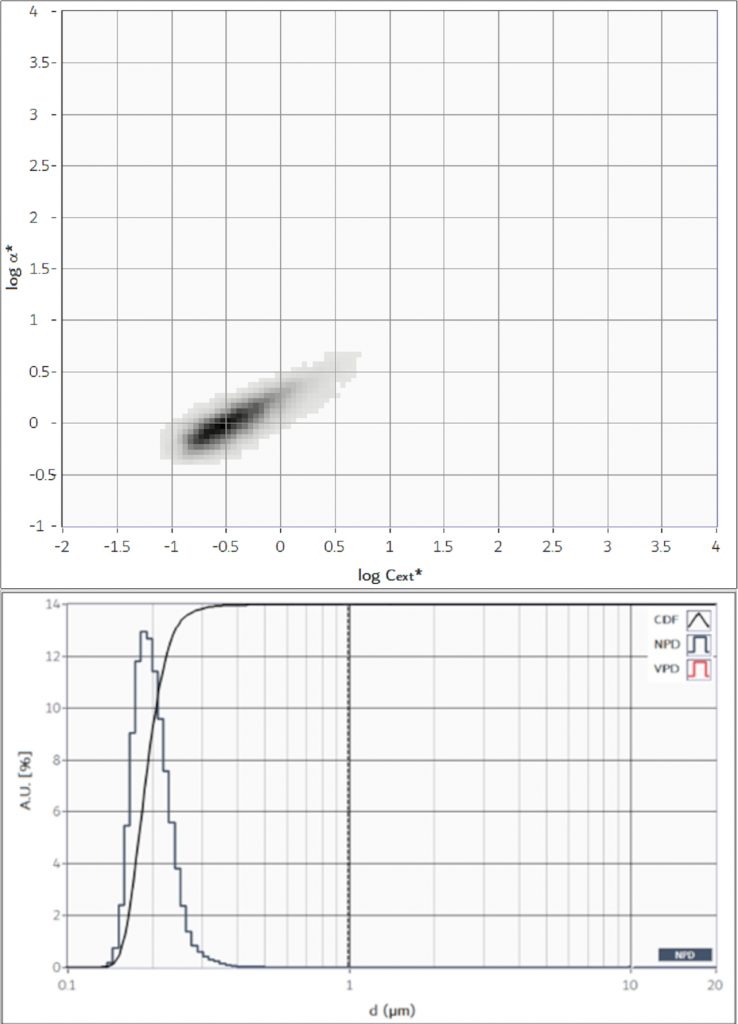

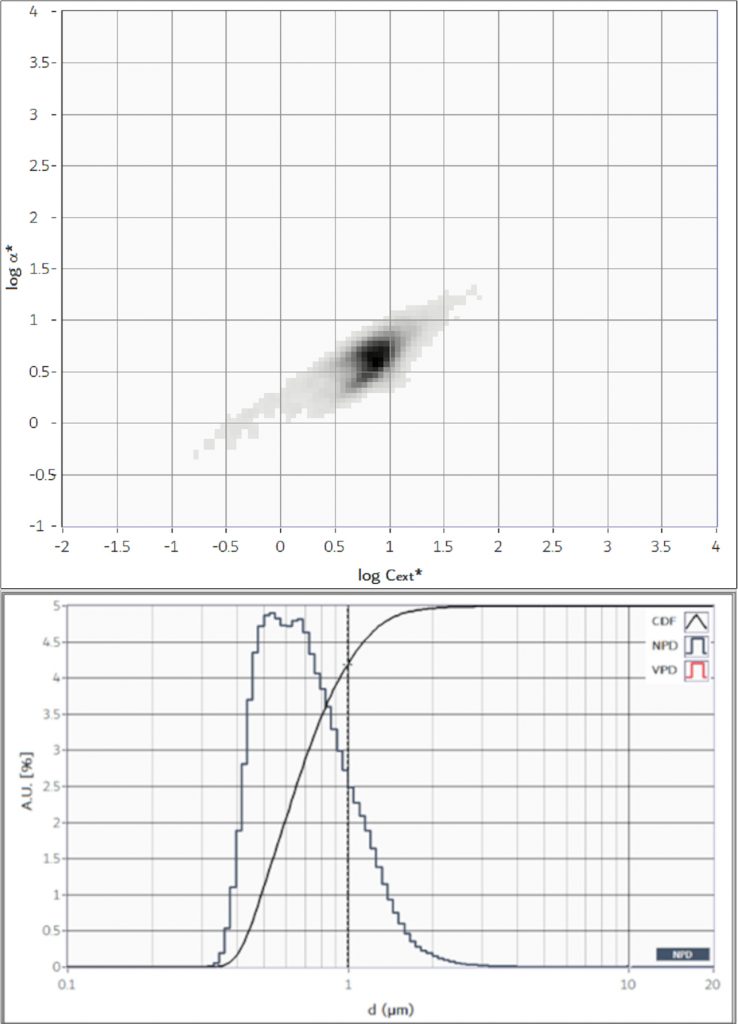

Slurries are aqueous dispersions of compact or mesopouros particles required by the most advanced technology for the silicon-based products, but found applications also in a number of industrial processes such as production of compact disks, hard disks and optical surface polishing. The characteristics of the abrasive material, their structure and size distribution typically play an important role in determining their removal properties. CLASSIZER™ ONE is the perfect tool for charactering both the size distribution, compactners of the mesopouros structure and the presence of solid contaminant or subvisible/submicron-scale aggregates.

Top menu

- EOS Technologies

- Products

- Applications

- Submicron and micrometric polymeric particle dispersions

- Particle behaviour in heterogeneous biofluids

- Metallic, Silver and Gold Particles

- Delivery Systems

- Pigments and Inks

- Oils and Lubricants QC

- Ground Powders and Minerals

- Emulsions, Liposomes, and Microcapsules

- Food & Beverage

- Cell Analysis

- Abrasives and Slurries

- Environmental Studies

- Aerosol

- Publications

- Testimonials

- Support

- Contract Analysis Services

- EOS Technologies

- Products

- Applications

- Submicron and micrometric polymeric particle dispersions

- Particle behaviour in heterogeneous biofluids

- Metallic, Silver and Gold Particles

- Delivery Systems

- Pigments and Inks

- Oils and Lubricants QC

- Ground Powders and Minerals

- Emulsions, Liposomes, and Microcapsules

- Food & Beverage

- Cell Analysis

- Abrasives and Slurries

- Environmental Studies

- Aerosol

- Publications

- Testimonials

- Support

- Contract Analysis Services

Abrasives and Slurries

You are here:

- Home

- Applications

- Abrasives and Slurries