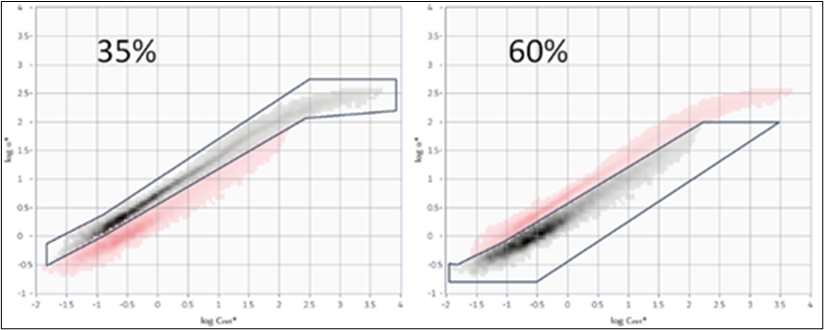

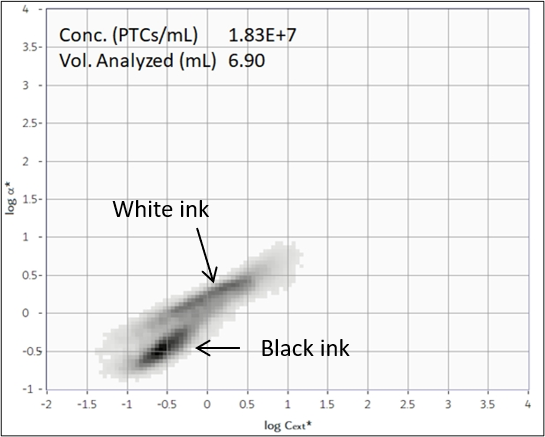

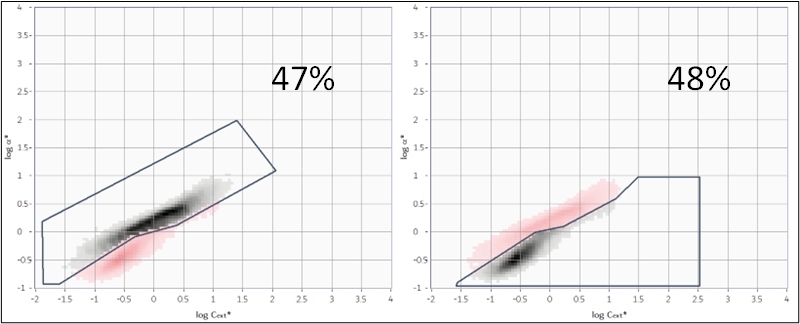

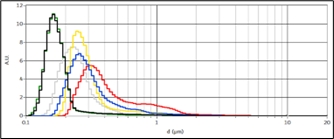

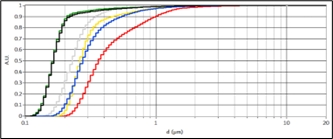

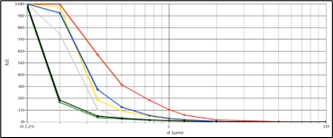

A broad collection of pigment, powder coatings, and ink products exist as particulate form in both the raw material and finished product. The particle size distribution determines their appearance, quality, functionality and processability, thus measuring the pigment particle size is as an excellent predictor of final product performance. Moreover, particle size of pigment particles in paint is a critical parameter that affects surface finish. As for example, cosmetic industry is always looking for the best mix between creativity and innovation and color pigments cover a fundamental role in this. To create metallic effects, white, interference, reflections, particles with adequate characteristics have to be selected. Classizer™ ONE is an enabling device supporting product formulation, thanks to its performances in charactering particle size distribution, composition, shape, best surfactant and the stability of pigments, inks, and cosmetics powders.

Top menu

- EOS Technologies

- Products

- Applications

- Submicron and micrometric polymeric particle dispersions

- Particle behaviour in heterogeneous biofluids

- Metallic, Silver and Gold Particles

- Delivery Systems

- Pigments and Inks

- Oils and Lubricants QC

- Ground Powders and Minerals

- Emulsions, Liposomes, and Microcapsules

- Food & Beverage

- Cell Analysis

- Abrasives and Slurries

- Environmental Studies

- Aerosol

- Publications

- Testimonials

- Support

- Contract Analysis Services

- EOS Technologies

- Products

- Applications

- Submicron and micrometric polymeric particle dispersions

- Particle behaviour in heterogeneous biofluids

- Metallic, Silver and Gold Particles

- Delivery Systems

- Pigments and Inks

- Oils and Lubricants QC

- Ground Powders and Minerals

- Emulsions, Liposomes, and Microcapsules

- Food & Beverage

- Cell Analysis

- Abrasives and Slurries

- Environmental Studies

- Aerosol

- Publications

- Testimonials

- Support

- Contract Analysis Services

Pigments and Inks

You are here:

- Home

- Applications

- Pigments and Inks